Introduction

Long distance control cables play a crucial role in various industries and applications where precise and reliable control is essential. From industrial machinery to underwater vehicles, these cables enable operators to remotely control equipment over extended distances with accuracy and efficiency. In this comprehensive guide, we will explore the different types of long distance control cables, their applications, advantages, and key considerations for selecting the right cable for your specific needs.

Types of Long Distance Control Cables

Long distance control cables come in a variety of types and constructions, each designed to meet specific performance requirements. Some of the most common types of control cables include:

1. Mechanical Control Cables: Mechanical control cables are used to transmit mechanical motion from one point to another. These cables are often used in applications such as steering systems in vehicles, throttle controls in aircraft, and control systems in industrial machinery. Mechanical control cables are typically made of high-strength materials such as stainless steel or galvanized steel to withstand high loads and provide reliable performance over long distances.

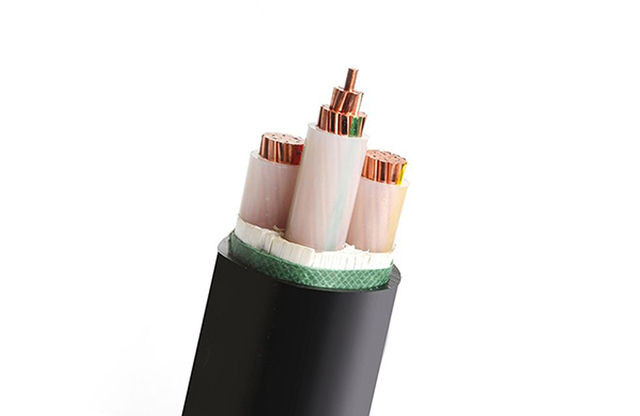

2. Electrical Control Cables: Electrical control cables are designed to transmit electrical signals from a control device to a remote actuator or sensor. These cables are commonly used in automation systems, robotics, and other applications where precise control of electrical devices is required. Electrical control cables are insulated to protect against electrical interference and environmental factors, ensuring reliable signal transmission over long distances.

3. Fiber Optic Control Cables: Fiber optic control cables use optical fibers to transmit control signals instead of traditional electrical conductors. These cables offer high-speed data transmission, immunity to electromagnetic interference, and greater bandwidth compared to electrical control cables. insulated sheathed power cable are commonly used in telecommunications, data centers, and industrial control systems where high-speed and reliable communication is essential.

4. Hydraulic Control Cables: Hydraulic control cables are used to transmit hydraulic fluid from a control system to a remote actuator or hydraulic cylinder. These cables are commonly used in heavy machinery, construction equipment, and aerospace applications where precise control of hydraulic systems is critical. Hydraulic control cables are designed to withstand high pressures and provide smooth and reliable operation over long distances.

Applications of Long Distance Control Cables

Long distance control cables find applications across a wide range of industries and sectors where remote control and automation are essential. Some common applications of long distance control cables include:

1. Industrial Automation: Long distance control cables are used in industrial automation systems to control machinery, robots, and other equipment from a central control station. These cables enable operators to remotely monitor and adjust operation parameters, improving efficiency and productivity in manufacturing and processing plants.

2. Remote Monitoring Systems: Long distance control cables are used in remote monitoring systems to transmit data and control signals from sensors and cameras to a central monitoring station. These cables are essential for monitoring critical infrastructure, such as oil and gas pipelines, power plants, and railway networks, ensuring timely detection of faults and emergencies.

3. Marine and Offshore Applications: Long distance control cables are used in marine and offshore applications to control navigation systems, propulsion systems, and other equipment on ships, submarines, and offshore platforms. These cables are designed to withstand harsh environmental conditions, such as saltwater corrosion and extreme temperatures, ensuring reliable operation in maritime environments.

4. Aerospace and Defense: Long distance control cables play a crucial role in aerospace and defense applications, where precision control and reliability are paramount. These cables are used in aircraft control systems, missile guidance systems, and unmanned aerial vehicles (UAVs), enabling pilots and operators to remotely control flight and navigation functions with accuracy and safety.

Advantages of Long Distance Control Cables

Long distance control cables offer several advantages over wireless control systems and other communication methods. Some of the key advantages of long distance control cables include:

1. Reliability: Long distance control cables provide a reliable and secure connection between the control device and the remote equipment, ensuring consistent performance even in challenging environments. Unlike wireless systems, which can be susceptible to interference and signal loss, control cables offer a stable and uninterrupted communication link over long distances.

2. Precision Control: Long distance control cables enable operators to achieve precise control over equipment and machinery, allowing for accurate positioning, speed control, and parameter adjustments. This level of precision is essential in applications where safety, efficiency, and accuracy are critical, such as in industrial automation and aerospace systems.

3. Durability: Long distance control cables are designed to withstand harsh environmental conditions, mechanical stress, and other challenges encountered in industrial and outdoor settings. These cables are built to last, with high-quality materials and construction that ensure long-term reliability and performance under demanding conditions.

4. Security: Long distance control cables offer enhanced security compared to wireless control systems, as they are not susceptible to hacking or unauthorized access. This makes control cables ideal for applications where data integrity and confidentiality are essential, such as in military and defense systems, critical infrastructure, and confidential communications.

Considerations for Selecting Long Distance Control Cables

When selecting long distance control cables for your specific application, it is important to consider several key factors to ensure optimal performance and reliability. Some of the main considerations include:

1. Cable Type: Determine the type of control cable that best suits your application requirements, whether it is mechanical, electrical, fiber optic, or hydraulic. Each cable type offers specific advantages and performance characteristics, depending on the nature of the control signals and environmental conditions.

2. Distance and Signal Transmission: Consider the distance over which the control signals need to be transmitted and the required signal integrity and reliability. Choose a control cable that can effectively transmit signals over the desired distance without signal degradation or loss.

3. Environmental Factors: Evaluate the environmental conditions in which the control cables will be installed, such as temperature extremes, moisture, chemicals, and mechanical stress. Select control cables that are designed to withstand these environmental factors and provide long-term durability and performance.

4. Installation and Maintenance: Consider the ease of installation and maintenance of the control cables, as well as any special requirements for cable routing, termination, and connection. Choose cables that are easy to install and maintain to minimize downtime and operational disruptions.

5. Compliance and Standards: Ensure that the selected control cables comply with industry standards and regulations for safety, performance, and reliability. Look for cables that are certified and tested to meet relevant standards, such as UL, CSA, and RoHS compliance.

Conclusion

Long distance control cables are essential components in a wide range of applications where remote control, automation, and precision are critical. These cables enable operators to control equipment and machinery over extended distances with reliability, accuracy, and efficiency. By understanding the different types of control cables, their applications, advantages, and key considerations for selection, you can choose the right cable for your specific needs and ensure optimal performance in your control systems. Whether in industrial automation, marine applications, aerospace systems, or other sectors, long distance control cables play a vital role in enabling remote control and communication in today's interconnected world.